EUROPEAN SILICON SUPPLY

The FORESi project

FORESi is a 3-year project that aims at FOstering a Recycled European Silicon Supply

The FORESi project is a 3-year EU-funded project that started in January 2024. It aims at FOstering a Recycled European Silicon Supply through the world’s first industrial demonstration of a cradle-to-cradle silicon value chain.

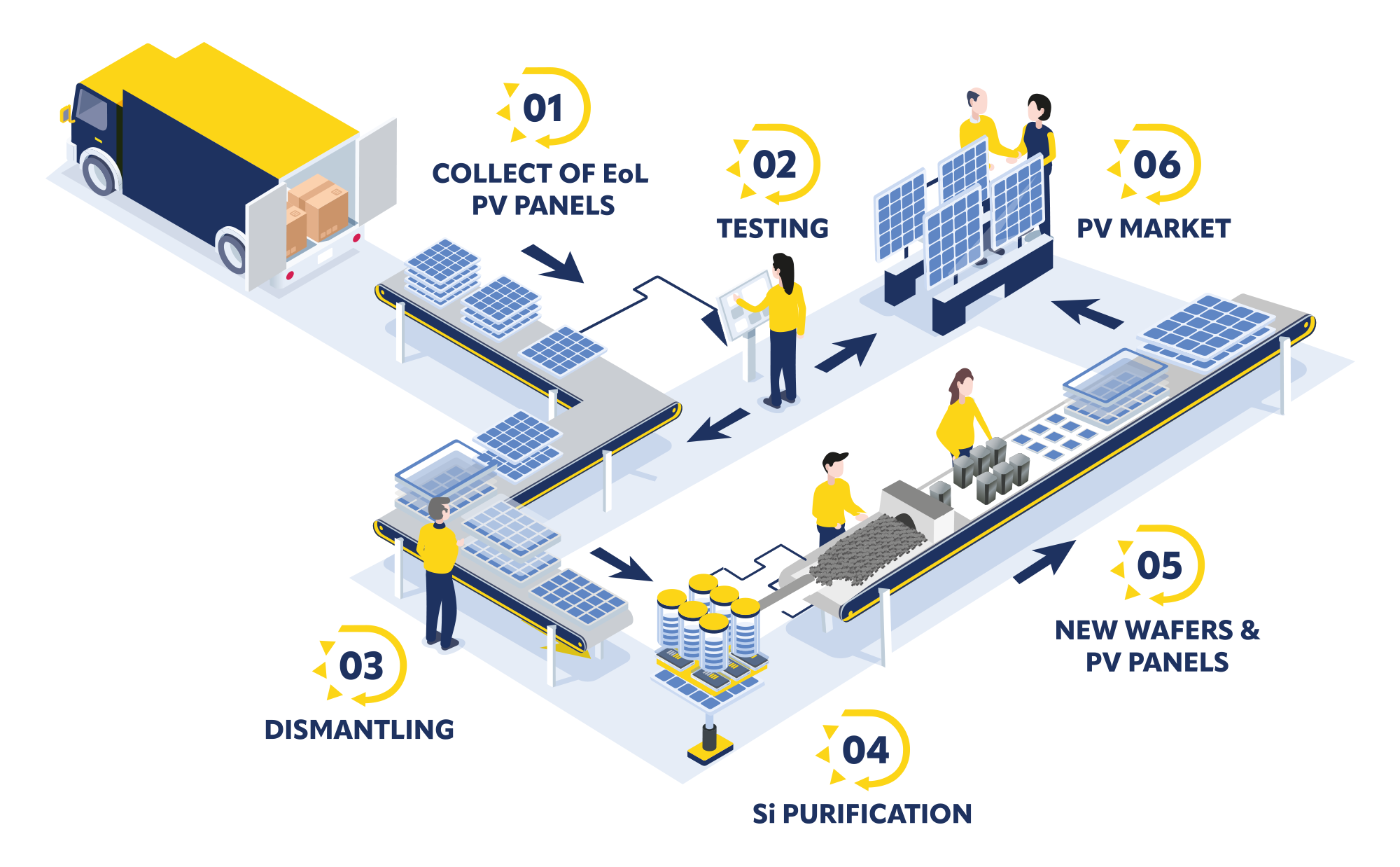

In order to contribute to a sustainable energy sovereignty for Europe, FORESi will demonstrate a circular recycling process from end-of-life photovoltaic (PV) panels to new PV and EV batteries applications.

The project will demonstrate the technical, economic and environmental viability of the entire recycling process and deliver the design of an optimised turnkey recycling factory for end-of-life PV panels, paving the way for European industrial mass production of recycled silicon.

FORESi will also develop an integrated online platform for the collection of PV modules and provide a PV testing methodology for the reuse and repair of EoL PV modules.

6 innovations

FORESi will demonstrate 6 different innovations,

each of them covering one part of the PV recycling value chain.

-

Recovery of end-of-life PV panels

FORESi focuses on improving the management of end-of-life photovoltaic (PV) panels through a comprehensive approach aimed at improving collection logistics. A comparative survey of panel collection logistics is being conducted, the findings of which will be used to develop best practices for PV collection logistics at both European and national levels, ensuring a standardised and efficient approach to the end-of-life management of PV panels.

-

Testing for reuse or repair

FORESi Innovation is advancing the field of PV panel recovery by developing a comprehensive test methodology to determine the economic viability of repairing end-of-life panels. This initiative includes the creation of a detailed list of tests and a decision tree to effectively sort panels for recycling, repair or reuse. By improving the logistics and technical testing processes, FORESi aims to extend the life of PV panels, thereby reducing material waste and CO2 emissions. In addition, an integrated online platform for PV recovery technologies will be developed and initially demonstrated in Slovakia, with plans for expansion across the EU.

-

Dismantling

FORESi aims to assemble and demonstrate a fully automated dismantling unit for end-of-life photovoltaic (PV) modules, enabling the consortium to build a replicable cradle-to-cradle PV recycling factory.

Based on the market and technical analysis, the automated dismantling machine will be purchased and assembled. The process will be demonstrated and optimised over the course of the project. This approach will ensure efficient, scalable and sustainable recycling of PV modules. -

Extraction of Silicon

The FORESi project will demonstrate an innovative, fully automated separation and Si extraction process. Unlike traditional methods that crush or shred the laminated components of photovoltaic panels, FORESi's technique preserves the integrity of the PVB/EVA film. This meticulous approach ensures higher material recovery rates compared to conventional shredding technologies, making it both more efficient and environmentally friendly. In addition, the process is designed to be replicable and scalable, providing a sustainable and advanced solution for silicon recovery that can be implemented on a larger scale across the industry.

-

Purification of Silicon

FORESi will demonstrate an innovative Si purification process that achieves the required purification levels of silicon while reaching better energy harvesting performance, when compared to conventional industrial methods on the market. The method will be implemented and optimised to achieve the highest level of purity and quality ensuring optimal performance, efficiency, and consistency in the purification of recovered silicon. This technology presents a sustainable approach to recovering resources from EoL PV panels, contributing to resource conservation, environmental responsibility and return on investment.

-

New production of silicon for batteries and solar applications

FORESi aims to prepare future ingots, cells, and modules using recycled Si feedstock. Additionally, this recycled silicon can be supplied to highly pure silicon users such as nano silicon producers and lithium battery manufacturers. To ensure the sustainability of the recycled silicon for high-efficiency photovoltaic modules, FORESi will assess its compliance with manufacturing standards. This includes evaluating the quality of the recycled feedstock by growing a reference monocrystalline silicon ingot and comparing the properties of ingots, wafers, cells and modules made from recycled Si with the reference material. Based on the results, the consortium may proceed with the fabrication and evaluation of new modules containing a percentage of recycled Si.

FORESi’s

specific objectives

Develop and demonstrate new PV logistics collection, reuse and repair processes at EU level.

Demonstrate a fully automated dismantling machine and a novel sustainable process for the recycling of end-of-life PV modules with a target recovery rate of at least 95%.

Demonstrate at industrial scale a new process for purifying silicon from various waste materials to produce High Pure Monocrystalline Silicon.

Demonstrate the circularity potential of the PV value chain by producing new solar cells with up to 15% upcycled silicon from end-of-life PV modules.

Evaluate and define the optimal parameters to achieve the highest economic, technical, social and environmental impact along the recycling value chain.

Provide a design for a turnkey PV recycling factory together with EU policy recommendations to increase the sustainability and future resilience of the European silicon PV value chain.

Ensure the long-term scale-up of FORESi innovations through realistic exploitation strategies, inter-cluster collaboration and stakeholder engagement.

Public deliverables will be posted here over the course of the project.